how do rivets work diagram

If the length of the hat is 12 the rivet has a 38 grip 375 also known as a 4-6 rivet. Snap head or cup head rivets.

It is used to joint structure member.

. The joints of this rivet are very strong. This type of rivets is shown in the figure. View chapter Purchase book.

Then both ends are formed over the connection joining the parts securely. When the tail is deformed it creates a second head on the other side of the assembly permanently locking. The metal work piece used to form the.

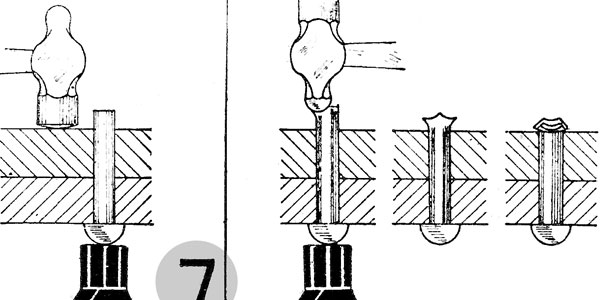

For installation the tail of the rivet is passed through the hole of the components they are to secure and the tail is then deformed with the use of a special tool. Select a drill bit that is smaller than the hole which your rivet is positioned in. Algorithm created to detect the angular orientation of the rivet works by first identifying the rivet and machine jaws using edge detection and threshold.

When calculating the suitable length of a Peeled rivet take the total thickness of materials to be fastened and add on double the rivets diameter. The head is of a semi-circle in shape. The end opposite to the head is called the tailOn installation the rivet is placed in a punched or drilled hole and the tail is upset or bucked ie deformed so that it expands to about 15 times the original shaft diameter holding the rivet in.

Exert body weight for holding firmly the gun against the rivet and the work-piece. A permanently formed head at each end prevents the rivet from being removed from the hole. This will ensure that it doesnt remove any unnecessary material from your work pieces.

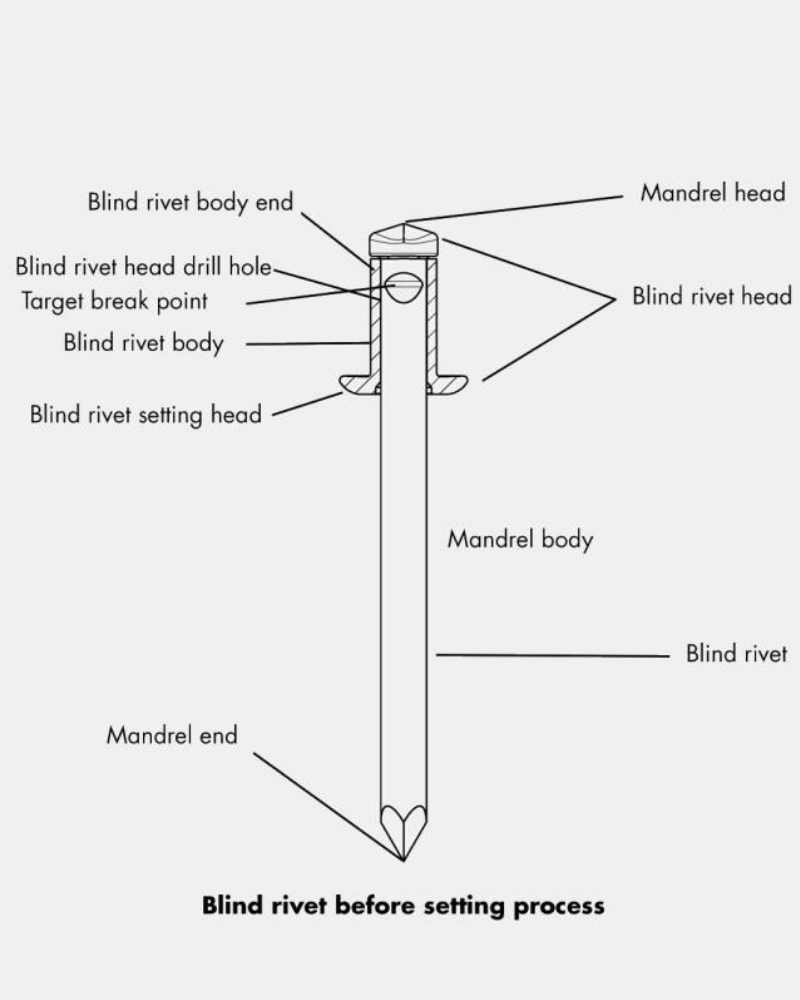

The basics of how a blind rivet works. Once gripped the mandrel snaps permanently holding the rivet in place. 10mm 96mm 196mm.

That is why it is widely used in bridges made of iron material. Hanson Rivet publishes its Know Your Rivets page to assist rivet users in the identification of rivet and threaded insert types and head styles. A pop rivet gun is placed on the rivet pulling the mandrel into the rivet body causing it to expand and grip the parts to be joined.

How do Rivets Work. Material thickness 10mm. To install place the rivet body into a hole in the materials to be joined until the rivet body lip is flush against the material surface.

A rivet is a permanent mechanical joint which are broadly used to joint structure ships barrels etc. Notice how in the diagram to the right the portion of the. Also featured are a number of special rivets and fasteners on.

The shaft prevents any radial movements of the components. Blind Rivet Guide - Specifications Information and Sizes of Pop Rivets. Riveting is a forging process that may be used to join parts together by way of a metal part called a rivet.

Tubular blind solid and split. Adjust the air regulator to help drive the rivet in some seconds. A straight metal piece will be inserted via the hole or cavity provided for.

Its diameter is 16D and its height is 07D. Standard rivets consist of an unthreaded cylindrical shaft and a head. Automatic feed riveting machines include a hopper and feed track which automatically delivers and presents the rivet to the setting tools which overcomes the need for the operator to position the rivet.

A rivet is a mechanical joint which is cylindrical in shape and having a head. Rivets consist of two parts. The rivet acts to join the parts through adjacent surfaces.

A rivet is a permanent mechanical fastenerBefore being installed a rivet consists of a smooth cylindrical shaft with a head on one end. This is commonly referred to as an interlock rivet. Structural rivets work slightly different from the typical blind rivet.

There are two basic types of threaded inserts. Once in place slide a rivet gun with the proper sized adapter over the rivet. Just in simple words the parts used to join together with the help of the rivet is known as the riveting process.

Choose a rivet length of 1821mm. Rivets can also cause part cracking and loose assembly is a common fault but it can be corrected by using a shorter rivet or a thicker washer 1. A structural blind rivet has a built-in internal locking mechanism that is designed to hold the mandrel inside of the rivet after the exposed portion snaps.

See how rivets work learn what tools to use how to measure install and remove them. Blind Rivet diameter 48mm x 2 96mm. These joints are widely used in ship and boiler industries to join the structure member.

The rivets are kind of the adjacent surfaces between the two parts to be joined. The rivet body A and the mandrel B see image below. Drill out the center of the rivet carefully.

The downward force required to deform the rivet with an automatic riveting machine is created by a motor and flywheel combination pneumatic cylinder or hydraulic. A pop rivet is then inserted through the drilled hole and the rivet body is brought into contact with the parts. There are four basic types of rivets.

Rivets with this kind of heads are used most of all. A straight metal piece is connected through the parts. A rivet is a mechanical fastener with a plane unthreaded shaft thats inserted through holes to join two or more parts together.

It is a permanent joint which mean. Follow up with a punch and a hammer. Learn to use the gun with one.

Mandrel - Long end that is. Please refer to the diagram and charts below for grip ranges. 2 What is rivet riveting process definition meaning Image.

This example shows how Rivets flexible type scale and spacing utilities can be combined to create layouts that work for all screens. Create a dashboard view for your app using Rivets mobile-first designed components. Try to hold the gun as close to perpendicular as possible.

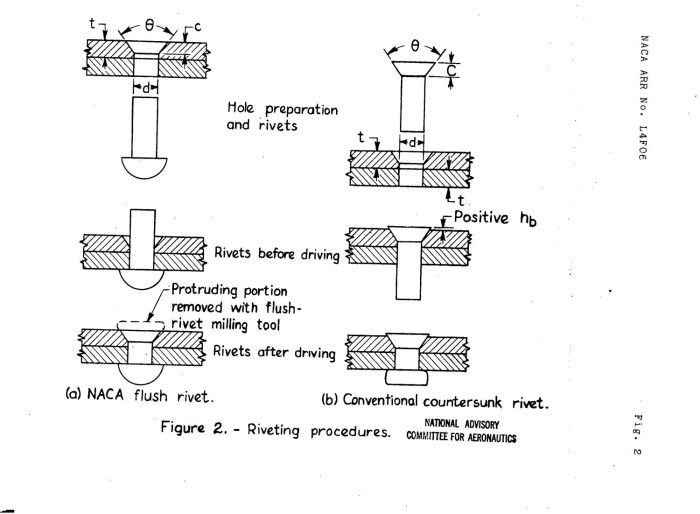

The Schematic Diagram Of The Riveting Process For The Countersunk Rivet Download Scientific Diagram

Blind Rivets Solid Rivets Rivets Metal Crafts Solid

Methods Of Riveting And Material Used For Rivets Extrudesign Machine Design Riveting Rivets

Rivet Types And Styles Riveting Rivets Soldering Jewelry

Schematic Diagram Of Friction Self Piercing Riveting Process A Rivet Download Scientific Diagram

Riveted Joints Definition Applications Operations Types Studentlesson

Rivets Plan Download Free Vintage Model Aircraft Plan Model Airplanes How To Plan Model Planes

What Is A Blind Pop Rivet Gesipa

Structural Fasteners Solid Shank Rivets Installation Of Rivets

4 Tips For Stronger Blind Rivet Joints Machine Design Machine Design Blinds Joint

How Rivets Work Rivets Fasteners Screwdriver

What Are The Types Of Rivet Heads According To The Indian Standards Machine Design Engineering Design Rivet

Usually Rivets From 3 16 Diameter Through 1 2 Are Easy To Obtain In Commonly Useful Lengths Custom Rivets Fo Blacksmithing Sheet Metal Tools Forging Tools

Illustration Of The Friction Stir Blind Riveting Process A The Download Scientific Diagram

What Is Rivet Definition Types Working Process Engineering Choice